Download your copy of “10 tips for correctly sizing electric axes” below!

Electric automation can offer greater efficiency, precision, and reliability than traditional pneumatic systems - but only if it’s designed correctly. Even small design mistakes can lead to costly downtime, inefficiencies, and unnecessary maintenance.

This guide delivers essential tips every engineer needs when designing positioning systems. Instantly accessible, it’s your go-to resource packed with expert insights. Grab your copy now!

Inside access: A key tip just for you!

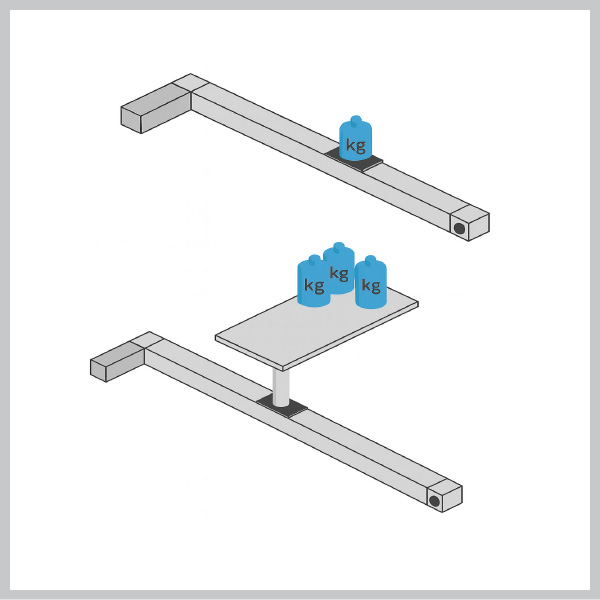

Account for the centre of gravity

- When choosing a linear axis, it’s not just the load’s weight, but its position relative to the carriage that matters.

- A load’s centre of gravity far from the carriage increases stress on guide bearings.

- Ignoring this can cause undersized axes and shorter service life.

- Festo software tools consider centre of mass and project parameters to select systems with reliable lifecycles.

This guide will:

Help you recognise and avoid the most common mistakes

Allow you to learn from other engineers as it is based on real examples

Develop your knowledge and assist you in designing better electrical positioning systems

Unlock more than just the guide! Download now to gain exclusive access to webinars and future content - available only to our guide readers.