Get clarity on one of the most important choices machine builders face

Build or buy? The AI decision that shaped your machines and your business

This guide helps OEMs choose the smartest path to predictive maintenance fast!

Download the 'make or buy?' decision guide

Confidently assess your options with a tool built for real world machine builders easy to share with technical and business teams alike

This guide explains:

- The full cost, risk and time to market trade offs of building vs buying AI

- What most OEMs underestimate when scoping internal AI projects

- How proven off the shelf apps can fast track your road map or compliment your own tools

This guide will help you:

Make a confident make-or-buy decision

Learn the essential criteria for choosing whether to develop AI software in-house or purchase from a trusted provider.

What's inside the Guide?

Discover what makes AI for industry so complex

Discover why industrial AI is unlike consumer AI and why deep mechatronics and IT/OT expertise matter.

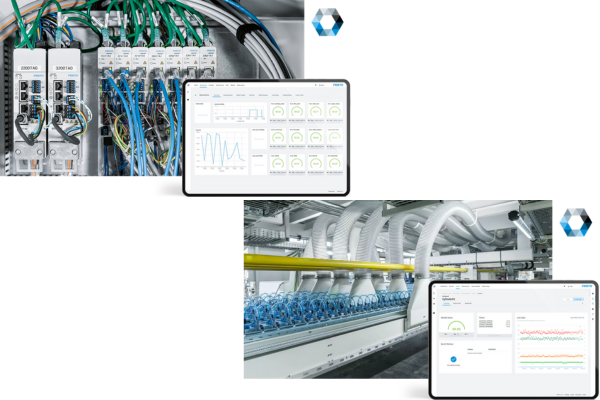

Why standardized AI apps are a strategic win

See how ready-made solutions like Festo AX Motion Insights Pneumatic and Festo AX Motion Insights Electric deliver value from day one without the need for in-house data science skills.

See how affordable an AI solution can be

Discover how much you could save with a proven, scalable AI solution for monitoring your pneumatic cylinders and Electric axes/servos. The guide reveals real-world pricing examples that show just how cost-effective it can be especially compared to in-house development.

How to select the right predictive maintenance software

Learn the key factors for choosing the right AI for manufacturing: IT/OT integration, scalability, maintenance cost reduction, data security, and factory uptime improvement.

Why Scalable AI Maintenance Apps Work for OEMs & End Users

Explore how plug-and-play AI tools help OEMs and end users optimise equipment efficiency, reduce downtime, and simplify maintenance without deep in-house AI expertise.