Build your air preparation unit

The answers to the 5 most frequently asked questions

Get insights on functions, sizing and selecting the right components for your air prep unit.

Download this whitepaper to learn how to choose the right components to ensure proper arming, air quality, and system configuration.

Why this whitepaper is essential:

- Learn how to determine the right size for your air preparation station

- Understand how to meet ISO 8573-1:2010 compressed air standards

- Learn what smart choices there are for soft-start and pressurisation modules

This whitepaper will help you to

Determine the functions you need

Choose the right components

Align with ISO and safety measures

What’s inside the whitepaper?

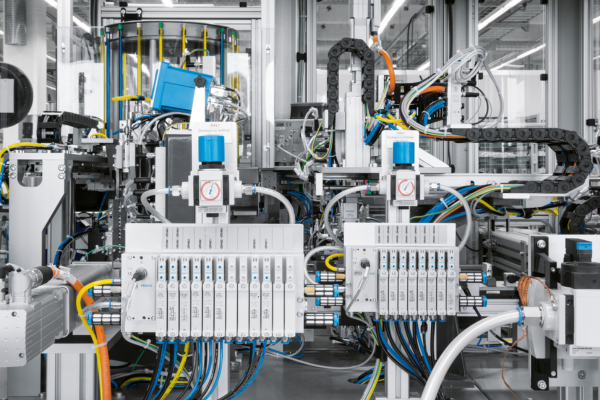

Build what you need

Choosing the right components is a complex task. Discover the specific roles of filters, regulators, lubricators, and more—modular or pre-assembled, tailored to your system’s needs.

Meet industry-specific demands

Different industries require different air quality levels. Explore how sectors like food, pharma, and electronics influence the selection of filtration and dehumidification components in air preparation systems.

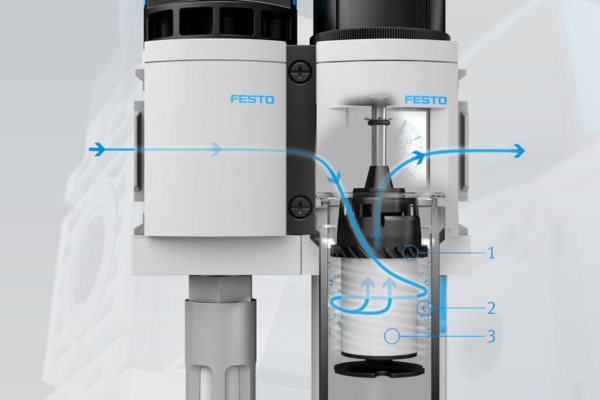

What air quality is required?

Air quality plays a key role in everything from extended component lifespans to critical industry standards. Learn how ISO 8573-1:2010 defines limits for particles, water, and oil.

Who should download?

Design and automation engineers focused on system performance

Machine Builders looking to reduce design complexity

Maintenance engineers aiming to reduce wear and unplanned downtime

Download now to improve system uptime, energy efficiency, and ease of maintenance with properly prepared air.