Do you have a new positioning system on your to-do list? A single axis with motor or a multi-axis system?

Reliable servo technology from Festo can help you solve your automation problems. In this section, we will give a brief overview of the components and tools we provide so you can select the servo solution that is most suitable for your application. Our featured products below, which are part of the blue star core range, are attractively priced and readily available. These products are EU made. We offer motors and servo drives that are optimally suited for accelerating or decelerating in the millisecond range. Festo products are also ideal for precisely controlling position, speed and torque or for controlling and maintaining specific positions with the highest possible precision.

Servo motors and multi-fieldbus protocol servo drives offering extensive connectivity options.

Servo drive CMMT-AS

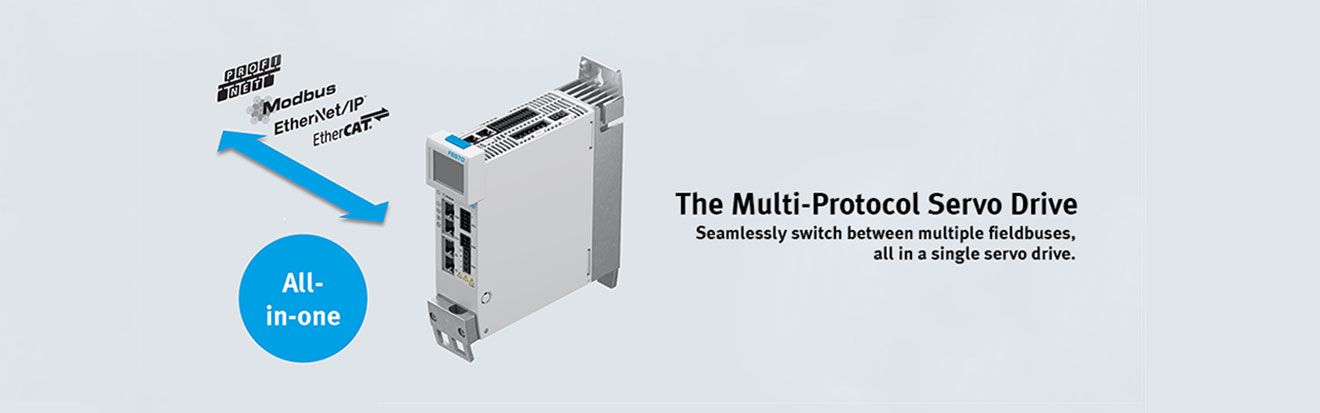

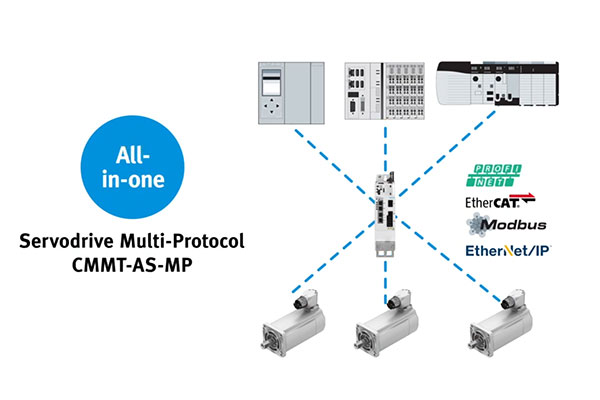

The multi-protocol servo drive CMMT-AS is part of our Core Range ensuring short lead times. This compact servo drive for point-to-point and interpolated motion is ideal for different Ethernet-based bus systems and can be directly integrated into most control system environments.

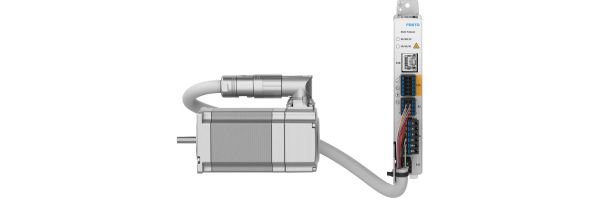

Servo motor EMMT-AS

Also included in the Festo Core Range. The motor combines maximum economy with maximum performance and offers a very low cogging torque, which ensures good controllability and track accuracy for positioning tasks. The simple connection technology (space-saving one-cable solution) and the 310° rotatable plug also allow it to be installed quickly and flexibly.

Servo lite: CMMT-ST and EMMT-ST

When it comes to tasks with low power requirements, the multi-protocol capable servo drive CMMT-ST combined with the stepper motor EMMT-ST is the ideal solution for simple positioning applications and point-to-point motion solutions.

The EMMT-ST enables a small step width at high driving torques, has optimised connection technology and is available in four sizes with flange dimensions 28, 42, 57 and 87.

Servo Starter Kit

Festo has once again put together a Servo Starter Kit for you. This kit contains everything you need to test our servo drives in your environment.

- Servo drive CMMT-ST-MP

- Motor cable (1.5 m)

- Stepper motor with absolute encoder EMMT-ST-42

Thanks to its multiprotocol networking capabilities, this drive can be controlled via Profinet, EtherCat, Ethernet/IP and Modbus, and its intuitive configuration software makes start-up faster than ever.

More information can be downloaded here.

Contact our experts!

If you have any further questions or need assistance selecting or sizing the correct components for your specific application, we are always happy to help.

Damian Gray

Senior Application Engineer

Festo Ireland

This might also be of interest!

View our innovations in Electrical Automation

By downloading the guide, you'll learn how these modular components can simplify machine layouts and reduce installation costs. Immediate benefits include:

- Easier selection of available components.

- Faster commissioning of your systems.

- Long-term flexibility for future expansion

Learn how connectivity innovation in servo drives is making integration faster and easier

Are you faced with the challenge of integrating servo drives into your PLC, mechanical and software environment? It doesn't have to be risky, complex or time-consuming. There is a new way to get going faster and easier. This recording is ideal for anyone who would like to simplify and modularise their servo drives despite the challenge of using different PLCs. Also, electrical and controls engineers designing, specifying or upgrading their factory automation systems.

Ten most commonly made errors with electric axes

These insights are important for new machine designs. Next time you design a system, you can pay special attention to these points in order to avoid the most commonly made errors and ensure that the electric drives last their full life span. Download our Top Ten Tips for correctly sizing positioning systems