New industrial wiring learning solution

A turnkey project that builds proficiency with electrical installations

Proper industrial wiring creates safe, efficient, and code-compliant electrical systems that meet the needs of industrial facilities and minimizes risks of hazards, downtime, and equipment failure.

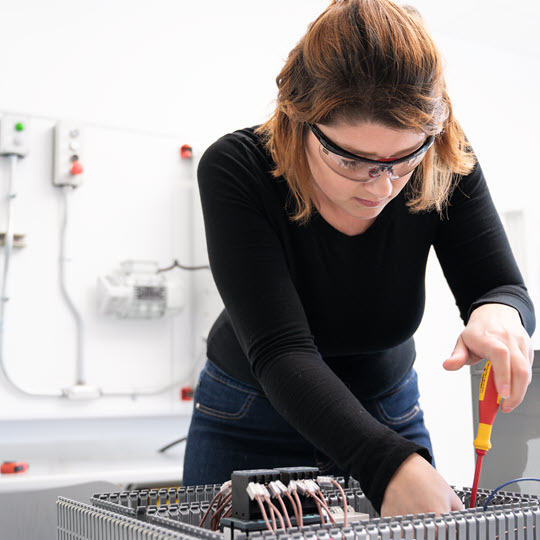

This requires the expertise of various skilled workers, such as panel builders and industrial electricians, as well as electrical and maintenance technicians. To work safely and efficiently, they must acquire proficiency in all the tools and techniques used in the workplace, which can be developed through well-structured, hands-on experimentation.

Our new industrial wiring project allows learners to develop a comprehensive and versatile skill set, as they gain expertise in the installation, commissioning, modification, and troubleshooting of an industrial electrical installation. Upon completion of the course, they will be well-prepared to tackle any wiring job with confidence!

Highlights

- Comprehensive, turnkey course material

- Typical, realistic project

- Industry-standard electrical schematics

- Safety components

- Three-phase electrical installation

- Compact and safe work environment

- Flexible packages to accommodate various needs

- Open design for potential custom projects

Offer a stimulating training opportunity with a real-life work scenario.

Learners install, wire, and commission an entire three-phase motor control system, including mounting and wiring the electrical panel with its control components.

This project can be used in school for regular laboratory sessions or as a capstone project to test students' skills. It can also be used for upskilling or reskilling current workers in industrial companies or for evaluating the wiring skills of prospective hires. Teachers or trainers can adapt the scope of the project to the needs of different job roles.

Main project tasks:

- Read electrical drawings

- Punch, deburr, and clean cutouts on the electrical enclosure

- Install the electrical enclosure, motor, and remote control station

- Install the junction box or conduit body

- Prepare and install rigid or flexible conduits and fittings

- Cut, strip, crimp, label, and properly connect wires and cables on the components

- Wire the electrical enclosure

- Run wires through flexible or rigid conduits

- Commission and troubleshoot, and maintain the installation, make modifications, and produce reports

Learners use the provided hardware to build this installation:

[1] 3-phase, 9-wire induction motor [2] Remote control station [3] Indicator light station [4] Built-in, non-removable safety devices [5] Removable electrical panel [6] Replaceable metal plates [7] Door with the main control panel (with stop/forward/reverse and stop buttons) and lockable main power switch [8] Grounded, tabletop workstation (optional) [9] Rigid conduits (optional) [10] Storage options (Systainers boxes, wire spool supports, etc.)

The course: the backbone of the learning experience

The course guides learners step-by-step throughout the project. Theory is introduced during the tasks. Videos and images demonstrate proper technics and tool usage. Pedagogical objectives are aligned to professional requirements.

The project-based pedagogical approach fosters an engaging learning experience, allowing learners to complete the project at their own pace. Instructors benefit from the turnkey and comprehensive nature of the curriculum, which saves them time and energy.

- Multimedia integration (animations, videos, pictures…) for enhanced learning

- Development of transversal skills (problem-solving, critical thinking, communication…)

- Course available as a digital course in our portal Festo LX or as a PDF or printed workbook

Get started with your ideal configuration.

Start with the basic industrial wiring system and select the options best suited to your needs.

Contact us today !