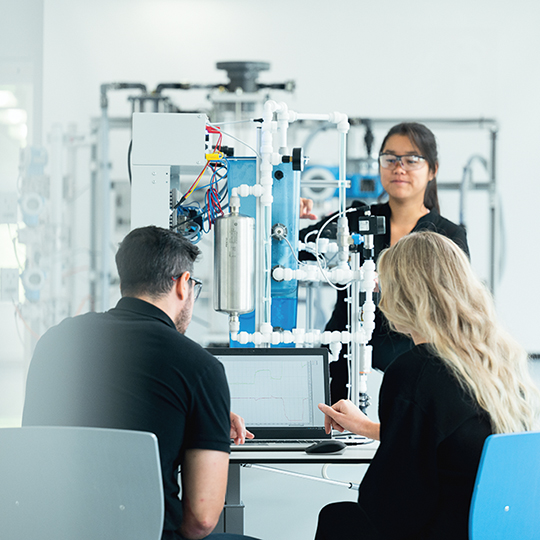

Introducing closed-loop control to beginners

Closed-loop control technology increases the efficiency, quality, and safety of modern process plants. To understand and approach complex control loops with confidence, future process operators and technicians need prerequisite foundational knowledge. How do you convey the basics of this control technology while mitigating its complexity?

The “Fundamentals of closed-loop control” course offers a user-friendly and professional introduction to the topic. Students can build universal skills required to work in the process industry:

- Commission and test a basic closed-loop system

- Read and design technical drawings for process engineering

- Perform analog signal processing

- Operate and analyze flow, level, pressure, and temperature control systems

- Select and use optimization methods for loop tuning

- Perform energy monitoring, analysis, and optimization of a pump

- And more

The course is available in our digital learning portal Festo LX or in print/PDF format.

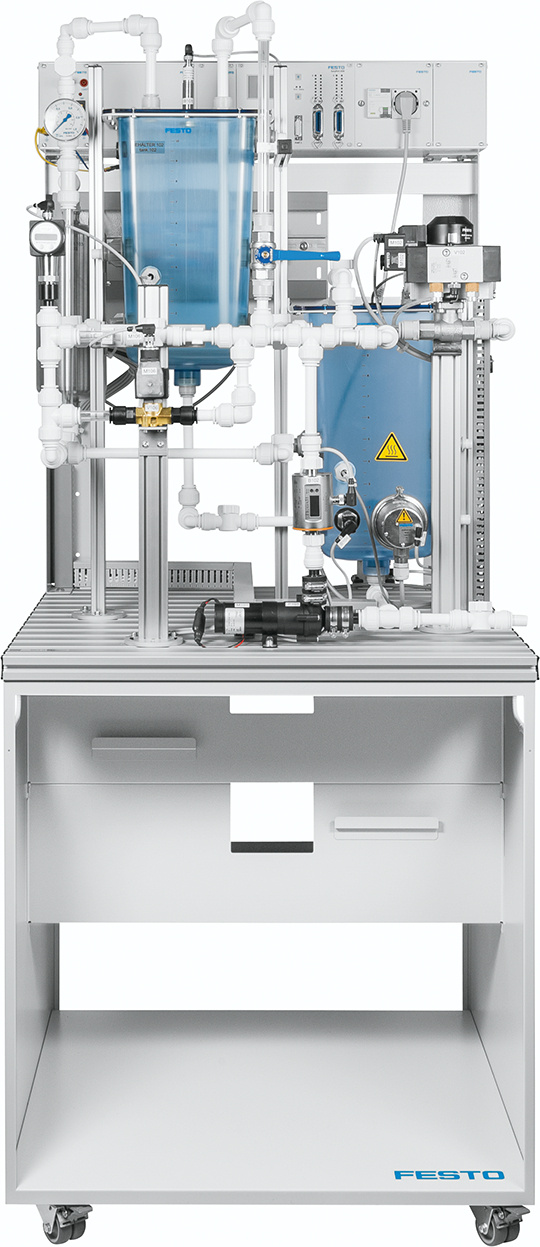

Practical experimentation is performed on the MPS PA Compact Workstation. See what students can do:

An ideal solution for learners and teachers:

Realistic

- Four typical control loops for the most common process variables

- Loops operated individually or in cascade

- Realistic components

- Interactive system

- PLC control possible

Complete

- Comprehensive course material focused on hands-on experimentation

- Coverage of all fundamental topics to build basic skills and knowledge

- Computer-based data acquisition and control

- Several possible configurations

User-friendly

- Simple and attractive design

- Compact and mobile

- Fixed component layout facilitates commissioning and use

- Transparent materials allows for easy observation

Customize the workstation to your requirements.

Workstation variants

• Basic design

• Process instrumentation

• Energy

Control options

• With a PC and a Festo HMI

• With a PC and FluidLab PA

• With a Siemens or Rockwell PLC and HMI

Optional components

• Cooling unit with heat exchanger

• IoT kit

Discover everything about this learning solution

Contact our Didactic experts today!