Avoid costly mistakes in electric axis design

Ten most commonly made errors with electric axes

Discover the most common errors engineers make and how to avoid them. Backed by global insights from real-world installations,

this guide is essential reading for anyone involved in machine design, engineering, or maintenance.

Designing electric axes for industrial automation? Don’t let overlooked details shorten your machine’s lifespan or compromise performance.

Fill out the form below to download your free copy and start designing smarter today.

Why this guide is essential:

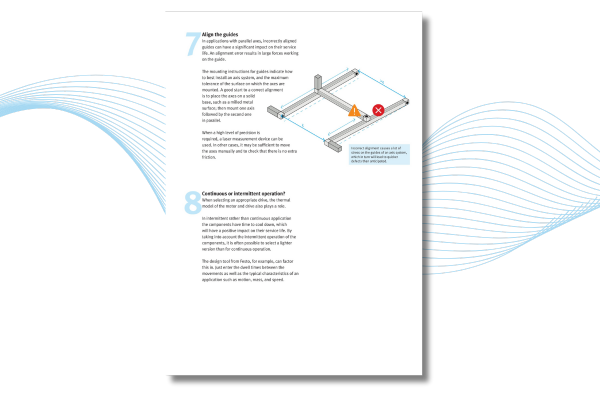

- Avoid the most common design and installation errors—from miscalculating axis orientation to underestimating vibration impact.

- Extend the service life of your systems by ensuring proper lubrication, alignment, and load distribution.

- Improve reliability and safety with insights on EMC interference, supply grid compatibility, and thermal modelling.

- Optimise cost and performance by choosing the right motor type and gear ratio for your application.

This guide will help you to:

Recognise and avoid the most common mistakes

Learn from real world examples

Develop your knowledge and assist you in building better machines

Real insights from the industry

Festo supplies electrical components across a wide range of industries and machines. When part of a machine doesn't function as intended or malfunctions, we investigate to determine why the system has not met the expected performance.

We collect and share these valuable insights with our customers to help them avoid similar problems in the future..

So for example, before your design your next electrical positioning system, remember to:

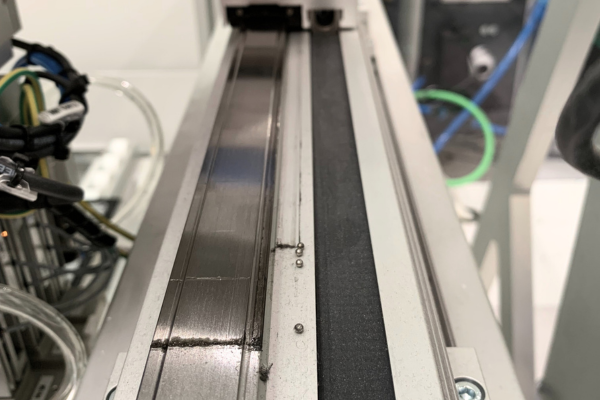

- Program a "lubrication cycle."

- Calculate the correct gear reduction ratio.

- Consider the impact of vibrations on performance.

Whether you're an OEM, machine builder, design engineer or maintenance professional, this guide empowers you to make smarter decisions and deliver more robust automation solutions. Don't miss out, download today!