Using a checklist to find the right automation components

Batteries for electromobility must be powerful and safe. However, quality problems during production can lead to reduced performance and high reject rates. Our 10-point checklist helps you to optimize quality and costs right from the start.

What added value does the checklist have for you?

Higher battery quality

The checklist helps you to produce high-quality, high-performance batteries. In this way, you gain the trust of your customers and avoid a high reject rate.

Optimized costs

Potential incompatibilities with your system can be identified at an early stage using the checklist, helping you avoid expensive bad investments.

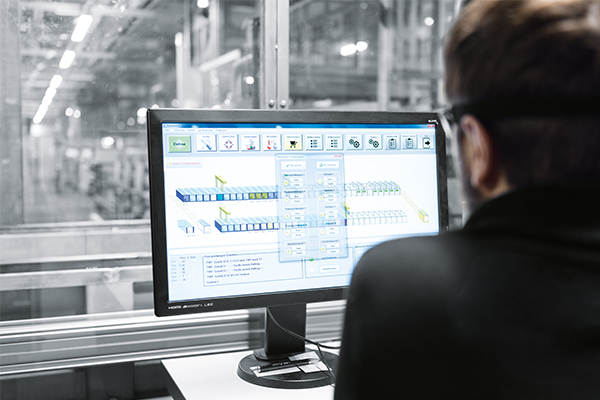

More efficient processes

On the safe side: With the checklist, you gain important insights into how you can optimally prepare and implement your processes as early as the planning phase.

Download your copy of the checklist now

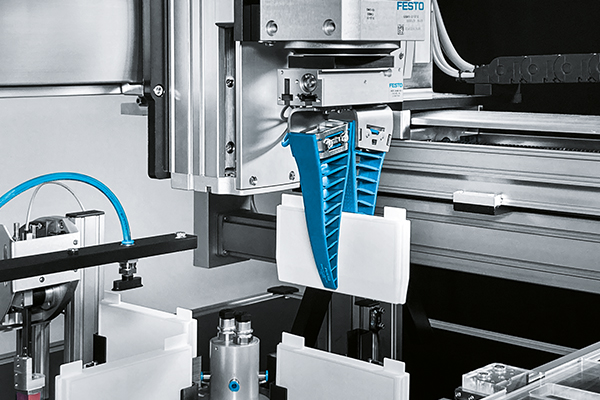

“Choosing the right automation solutions is the first step towards successful battery cell production.”

Jochen Luik

Global Industry Segment Manager Electronics

Festo SE & Co. KG