Using the e-book to find the right automation components

Batteries for electromobility must be powerful and safe. However, quality problems during production can lead to reduced performance and high scrap rates. Our e-book "The Key to the Safe Production of Battery Cells for Electric Cars. Copper-, nickel- and zinc-free automation components" helps you to optimize quality and costs right from the start.

What is the added value of the e-book for you?

Detecting impurities

The e-book helps you to detect the different types of impurities in battery production. This knowledge enables you to avoid contamination from the outset, and allows you to produce safe battery cells and control costs.

Understanding cleanrooms

The permissible particle concentration in the air in cleanrooms is regulated by the ISO 14644-1 standard. Find out more about a clean production environment. Internationally standardized norms can help to gain the trust of your customers.

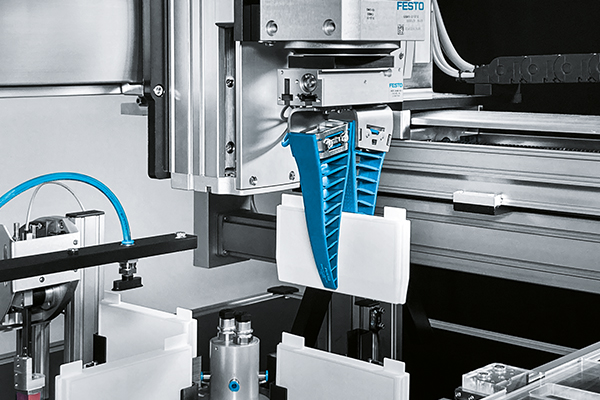

Selecting the right components

The product portfolio from Festo prevents contamination from occurring in the first place. The components contain virtually no copper, nickel, or zinc, which can be emitted through abrasion. The e-book helps you to make the right decisions when planning.

Download your copy of the e-book now

“Choosing the right automation solutions is the first step towards successful battery cell production.”

Jochen Luik

Global Industry Segment Manager Electronics

Festo SE & Co. KG