Minimising wear in your machines

Your compressed air network operates most efficiently when the amount of particles, oil and water is reduced and cannot cause any damage. The maintenance units of the MS basic series are ideal to help you keep the system running smoothly.

Factors influencing the smooth running/long service life of your machine

Particles

Water

Oil

Pressure

Flow

To prevent damage,

reduce the amount of particles,

water and oil in your

compressed air network

as much as necessary

Filter grades

with 5 μm or 40 μm inserts

To save energy,

shut off or reduce the pressure or flow

wherever possible

Pressure regulation

0 ... 10 bar

On/off intervals

per electric impulse

An overview of where to find specific information

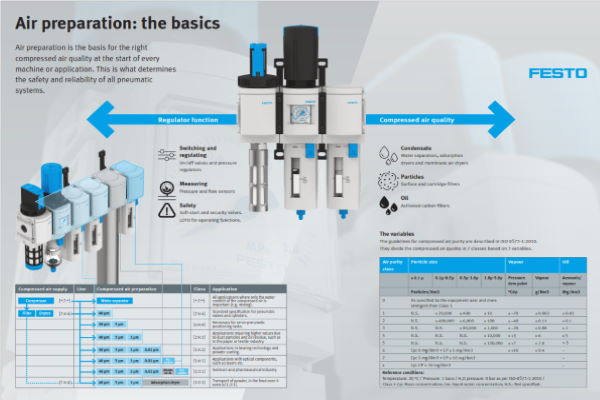

Air preparation: the basics

Avoid humidity and particles in your machine

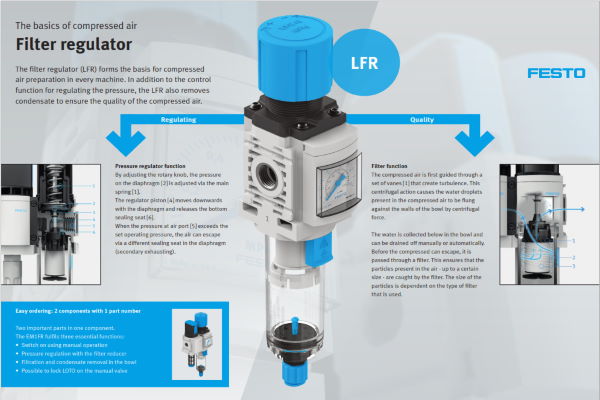

Filter regulator functionality

Use the right device xxxxxxxxxxxxxxx

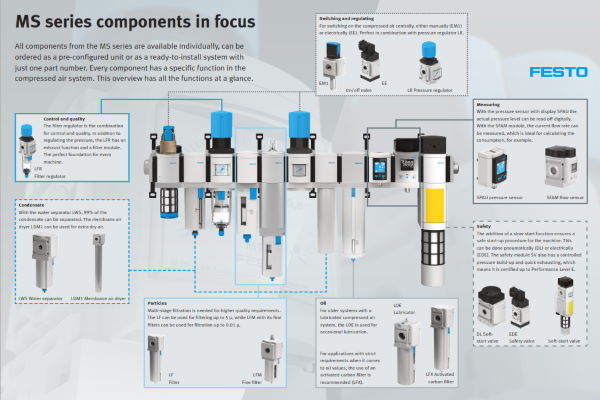

MS series components in focus

Take advantage of our modular series

Control and quality

Use the right size for the right flow rate

Reliable processes

Know the process of air preparation

White Paper

Combine methods of air preparation

Energy efficiency @ Festo

Find tips for energy efficiency xxxxxx