Step by step to the right pressure

The effort involved in changing a machine depends on the design, but the results can definitely make it worthwhile. Even just analysing and checking the pressure requirements could lead to a quick improvement and have a positive effects, while other modifications might be beneficial in the medium or long term.

Example of a machine optimisation using two different pressure levels

An example of a manufacturing cell optimisation shows how pressure supplied to different machine parts offers a huge energy-saving potential.

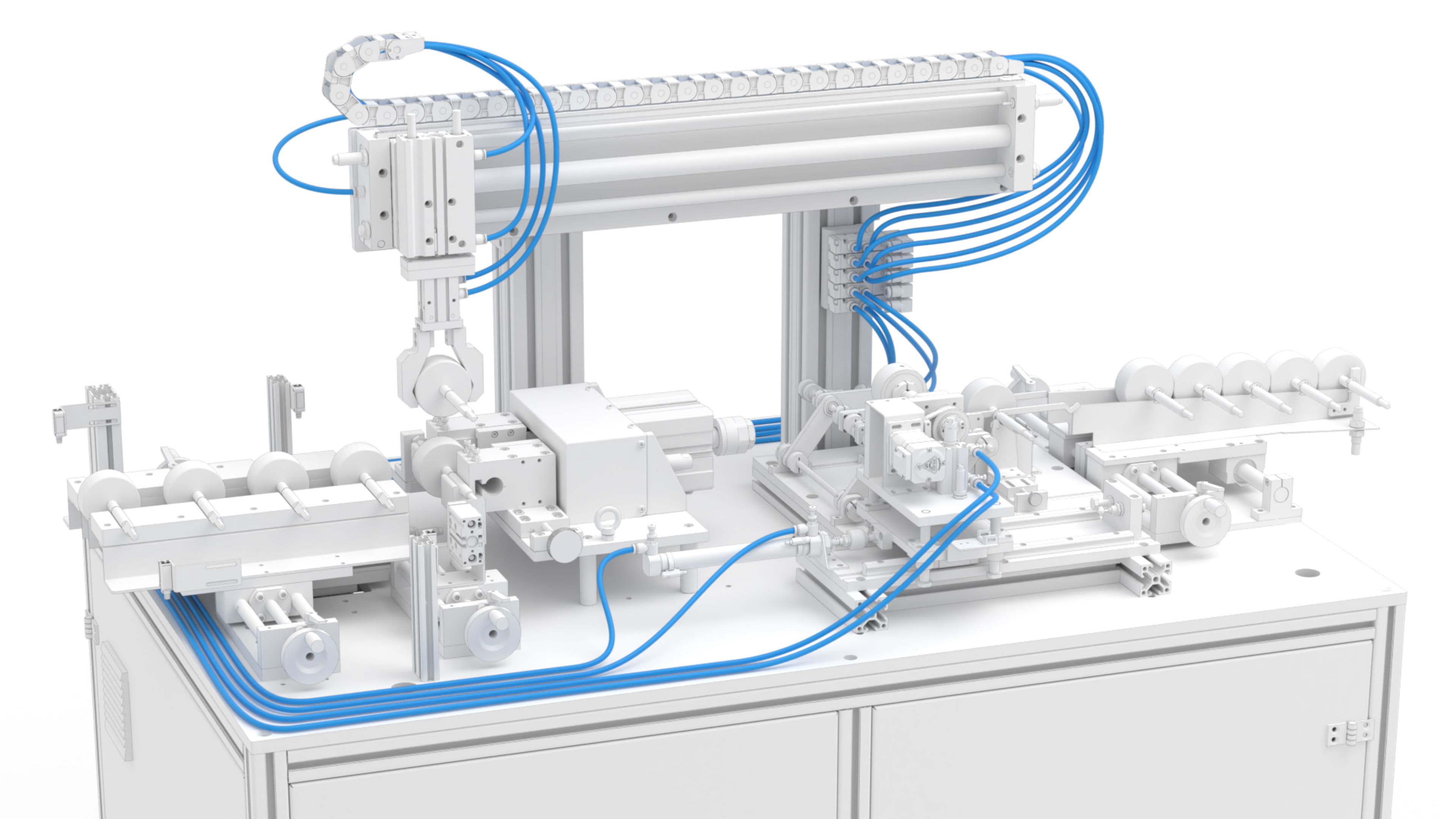

Before

Sample design

Machine concept before optimisation

Features of actual design (before)

- Pressure: 6 bar throughout

- Average tubing length: 2 m

- Capacity utilisation: 8 million units/year

- Consumption: 360 Nl/min

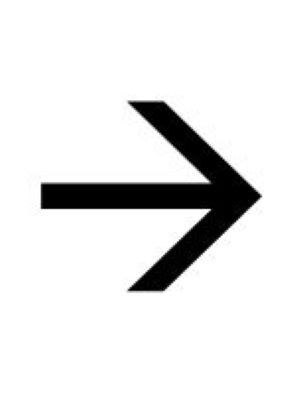

After

Machine concept after optimisation

Features of actual design (after)

- Two pressure zones: 5 bar and 3 bar

- Average tubing length: 0.72 m

- Capacity utilisation: 10 million units/year

- Consumption: 172 Nl/min

Changes made on the machine design

- Reduced tubing lengths

- Decentralised arrangement of the valve terminals

- Low and high pressure zones (3 and 5 bar)

- Modified actuation of blowing nozzles

- No oversized pneumatic actuators

Savings in the production

- Annual CO2 savings: 2.4 t

- Annual cost savings of consumed compressed air: € 875

Make the most of the MS basic series and our machine optimisation service

The MS basic is the latest addition to our MS series. It is lightweight, sturdy, attractively priced and a great asset for optimising your machines.

And why not check out our range of services on our website? Our offer includes air consumption analysis and an optimisation check of the entire machine. Following the analysis, we provide specific recommendations for improvement or even, should you wish, help with implementing the recommendations.

For a complete overview of our services click below.